In a previous article we published, we spoke about plant-based leathers. The wonderful part is, we live in a time and age when technology and innovation have ensured there’s no dearth of these plant-based vegan leather alternatives. As a part of Slow Fashion India’s Know Your Leather campaign, and in a continuation to the previous story, we’ve got you some more plant-based options you should know about, with two of these leather alternatives actually being produced by homegrown companies. Let’s have a look at how much prettier they are, for the planet as well as for the people working in the production cycle.

1. Fleather

Made from: Flower waste

The pretty: Phool, a Kanpur-based Indian startup, known for its charcoal-free, natural incense sticks and cones, and Florafoam (a compostable alternative to styrofoam) has now taken its flowercycling technology up a notch. Fleather (Flower + leather), which was a chance discovery, is made from the flower waste from temples and mosques being dumped into the River Ganga. According to estimates, over 8 metric tons of flower waste is dumped, daily. Since 2015, Phool have been instrumental in recycling more than 11,060 metric tons of flower waste, providing livelihood to over 1200 rural families, with 73 women working as flowercyclers.

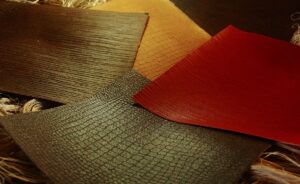

A dense, fibrous and mat material, Fleather resembles leather in appearance, elasticity and tensile strength. Tanned using a tree-bark powder solution, it can be dyed and embossed with a snake or crocodile leather pattern. Fleather is 100% biodegradable, and has been proven to be more breathable than the other alternatives available in the market. It also decomposes entirely in about 90 days, when buried in soil.

The not-so-pretty: Fleather was only discovered in 2021, so as of now, Phool’s lab has only developed the capacity to manufacture 840 sq m of the material each month–just enough to produce 2250 wallets. Scaling up will mean figuring out to grow larger Fleather sheets while maintaining the quality. Also, the material has a lower fibre density, which makes it unsuitable for sturdier items like belts that require tougher leather.

2. SCOBY leather

Made from: SCOBY (symbiotic culture of bacteria and yeast)

The pretty: A living culture cultivated from bacteria and yeast, with sugar as the fuel, SCOBY is the magic ingredient in Kombucha. The beauty of SCOBY is, you can save it to grow more SCOBYs. In fact, SCOBY has such a small carbon footprint, you can make your own at home, with this recipe.

The leather made from SCOBY is 100% biodegradable and vegan. It can be manipulated to be as thin, thick or flexible as desired. So, low-impact, great to use and biodegradable!

The not-so-pretty: SCOBY leather easily absorbs the moisture from the air and from the person wearing the material, softening the leather and making it less durable. On the other hand, the cold makes it brittle. The material shows a lot of promise, but it is still in the very early stages of innovation.

3. Apple leather

Made from: Apple pomace

The pretty: Alberto Volcan, an inventor from Italy, while looking for ways to use leftover apple waste from the fruit juice and the compote industry in Northern Italy came upon a sheet of fabric that resembled leather. This became the basis of Apple leather, known as AppleSkin. Due to the high cellulose content, apple pomace is ideal for upcycling into new fabrics. Developed further, and made commercially viable with Frumat, a company specialising in the recycling of industrial waste, this material is breathable, waterproof and durable.

Made from apple waste that is completely renewable, the CO2 impact is significantly lower in comparison to faux leather or traditional leather.

The not-so-pretty: AppleSkin is 50% apple waste mixed with 50% PU, coated onto a cotton/polyester canvas, effectively rendering it non-biodegradable. Despite being durable, the material is soft, making it suitable only for small accessories, like wallets and purses.

4. Wine leather

Made from: Grapes

The pretty: Wine, or Grape leather, is produced from the waste by-product of the Italian wine industry. This waste (pomace from the grapes, including the skins, pulp, seeds and stems of the fruit) was traditionally used as organic fertilizer or animal feed, but a Milan-based architect and founder of Vegea, a start-up tech company, Gianpiero decided to change that.

Vegea produces 2.6 billion square meters of wine leather, every year, just by using the wine production waste. Wine leather doesn’t need much water to be produced, and the wastewater is recyclable and can, therefore, be used over and over again. Vegea’s wine leather is being used in shoes, accessories, clothing and bags, and they are now working to expand it to produce upholstery and automobile accessories. The company has also introduced a concept of recycling, where the old wine leather products can be returned to dealers, recyclers etc, in exchange for a coupon and can further restore the old product by applying new wine leather.

The not-so-pretty: This bio-based product is coated onto organic cotton fabric, and the final product is made from 78 % eco-composite organic cotton and 22% water-based PU, making it non-biodegradable and difficult to recycle.

5. Banofi leather

Made from: Bananas

The pretty: India is the world’s largest producer of bananas, with more than 1 million banana farmers. Almost 4 tons of waste is generated for every 1 ton of fruit. Atma leather, a Kanpur-based company, is making Ban-o-Fi (Banana Fibre Leather) from banana fibres and agricultural waste, sourced directly from smallholder farmers, where this waste is not utilised. As they are fairly compensated for their produce, it disincentivizes crop burning practices.

With a significantly lower environmental impact than both animal and plastic leather, it has 100% reduced toxic wastewater and 90% less CO2 emissions. The materials have widespread applications, across fashion, furniture, automotives and packaging industries.

The not-so-pretty: Banofi is using 60% banana fibers, 20% natural additives and 20% synthetic additives, making biodegradability an issue.